فسازان

بیشتر بدانید

غلتک سازان سپاهان

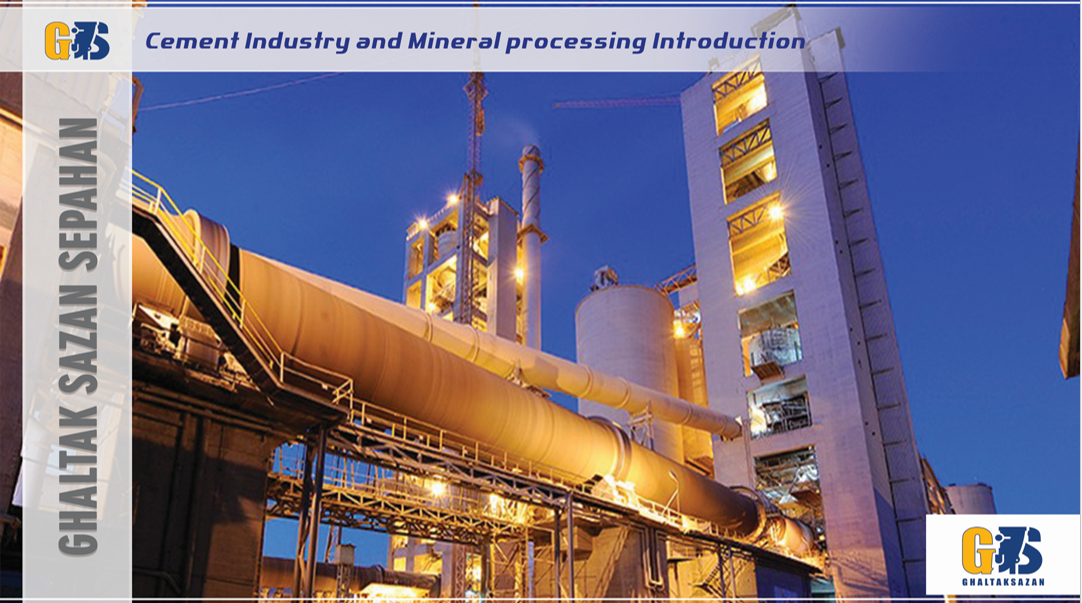

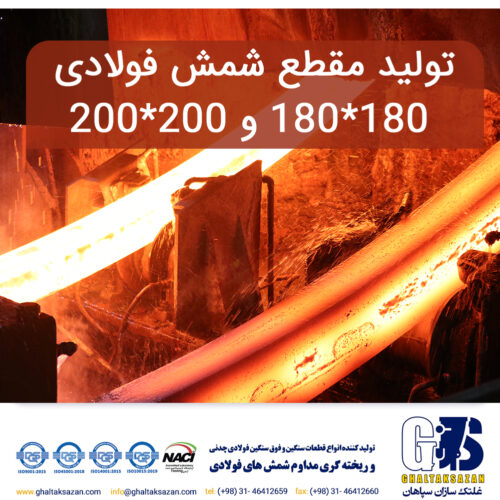

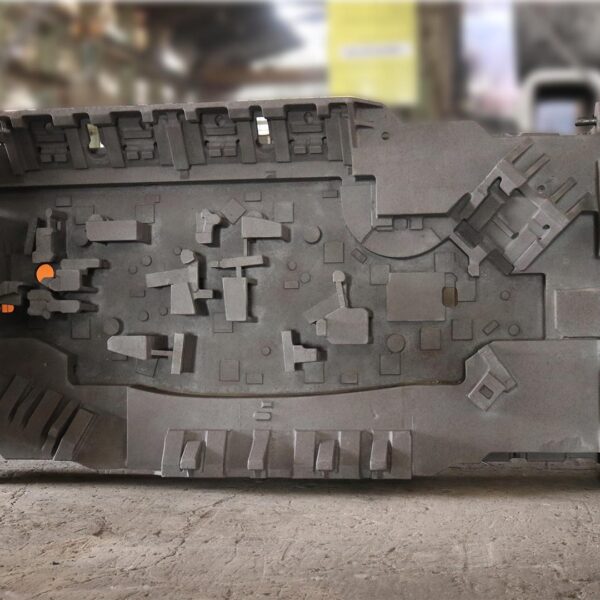

شركت غلتک سـازان سپاهان بعنوان يک مجموعه تخصصی و كيفی با هـدف ريخته گري قطعات سنگين و فوق سنگين چدنی و فولادی ، با ظرفيت توليد سـاليانه ۲۰ هزار تن انواع قطعات چدنی وفولادی تا وزن ۱۰۰ تن و همچنين ۱۵۰ هزار تن شمش فولادی به روش ريخته گری مداوم در زمينی به مساحت ۴۰ هزار متر مربع همراه با ۱۴ هزار متر مربع سالن های توليدی تأسيس گرديد. از سالن ها و فضاهای توليدي مي توان به سالن ريخته گری قطعات سنگين ،كوره های ذوب ، سالن ريخته گری پيوسته CCM ، سالن توليد غلتك های فوق سنگين از جمله غلتک های پشتيبان، سالن عمليات حرارتی كارگاه مدلسازی، انبارهای مواد اوليه و محصول، آزمايشگاهها و … اشاره كرد.

آخرین بروزرسانی ها و اخبار

گزیده خبرها

معرفی

واحد های داخلی

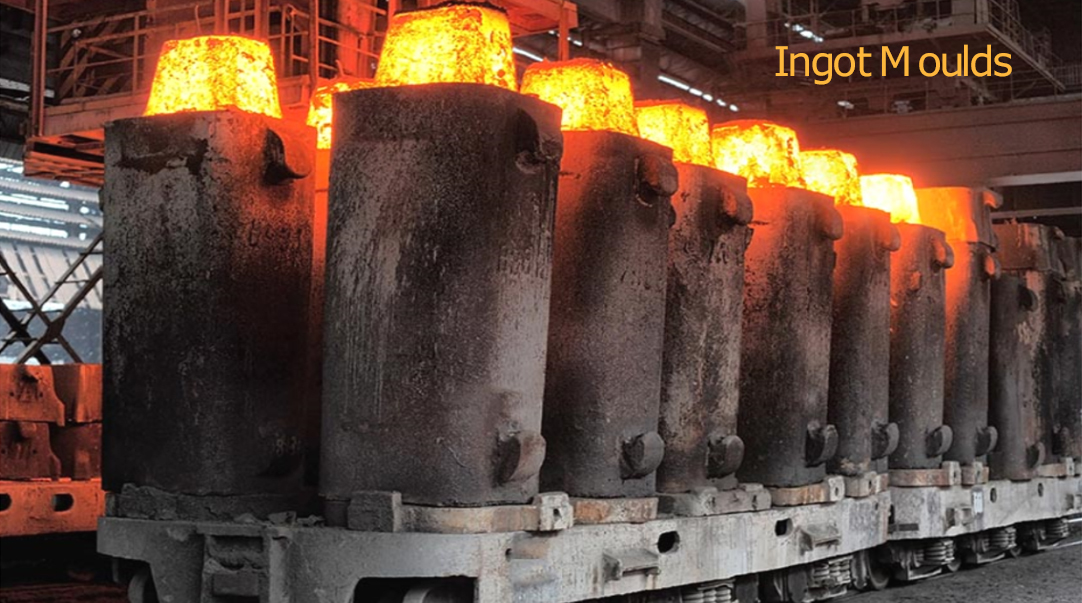

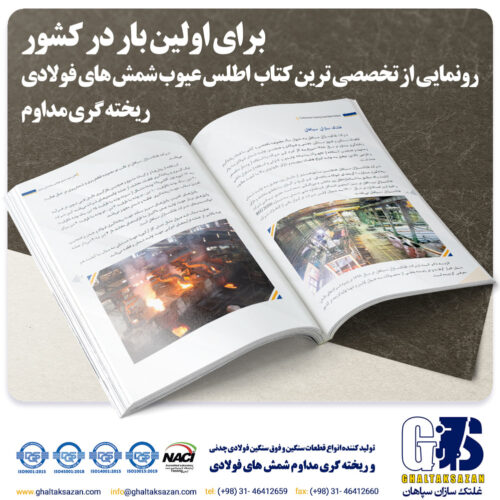

شرکت غلتک سازان سپاهان به عنوان یک شرکت دانش بنیانو پیشرو در صنعت فولاد و ریخته گری توانسته با تکیه بر دانش فنی و تخصص افراد کارآزموده خود، توانسته بخش عمده نیاز کشور را برآورده و از واردات محصولات و قطعات خاص جلوگری کرده و به عنوان یک شرکت شاخص به دنیا معرفی گردد.

شرکت غلتک سازان سپاهان با اخذ گواهینامه های بین المللی مختلف در راستای اعتلای سازمانی خود به عنوان یک شرکت صادرات گرا در سال 1400 از سوی سازمان مدیریت صنعتی کشور شناخته شود.

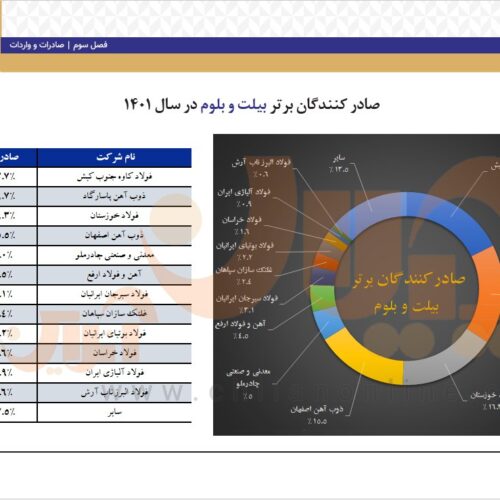

این شرکت به عنوان اولین دارنده نشان ملی استاندارد شمش در ایران معرفی شده که حدود 80% از تولیدات شمش خود را به کشور های مختلف صادر می نماید.